Summary PowerJet Pro Injector Cleaner & Tester Machine Kit

Summary PowerJet Pro 260 injector cleaner & tester uses ultrasonic technology to quickly remove carbon from the vehicle fuel system, and test leaking, uniformity, inbreath of injectors, so that the injectors can discharge fluid more quickly.

SUMMARY POWERJET PRO 260 injector cleaner & tester uses ultrasonic technology to quickly remove carbon from the vehicle fuel system, and test leaking, uniformity, inbreath of injectors, so that the injectors can discharge fluid more quickly.

SUMMARY POWERJET PRO 260 injector cleaner & tester fits for most petrol cars and motorcycles injectors, but NOT for diesel injectors. It also can be used for cleaning and testing six injectors at the same time.

Top Reasons Why You Need SUMMARY POWERJET PRO 260?

Fashionable and attractive appearance with the designers' ideas,

Support for optional spare parts purchase,

Support for measuring resistance,

Support for adjustable parameters.

3 years warranty for the host and 1 year warranty for consumable accessories.

Summary Product Comparison:

| Model | PowerJET GDI S4 | PowerJET Pro 260 | PowerJET Pro 240 | Summary machine can support all kinds of injector cleaning and testing |

| Picture |  |

|

|

|

| size | 355*350*380mm | 375*405*510mm | 355*350*380mm | |

| cylinders | 4 | 6 | 4 | |

| volume | 0.047 m3 | 0.077 m3 | 0.047 m3 | |

| weight | 12KG | 17KG | 11KG | Votec injector:

|

| Support low resistance injector (1-2Ω) test and cleaning function | Yes | Yes | Yes | |

| Support Top-feed fuel injector test & cleaning | Yes | Yes | Yes | Top-feed fuel injector:

|

| Support Side-feed fuel injector test & cleaning (With Optional Spare parts) |

Yes( standard configuration does NOT support.) | Yes( standard configuration does NOT support.) | Yes( standard configuration does NOT support.) | |

| Support GDI fuel injector test & cleaning | Yes | No | No | Side-feed fuel injector:

|

| Support GM TBI injector test & cleaning (With Optional Spare parts) |

Yes( standard configuration does NOT support.) | Yes( standard configuration does NOT support.) | Yes( standard configuration does NOT support.) | |

| Support Votec injector test & cleaning (With Optional Spare parts) |

Yes( standard configuration does NOT support.) | Yes( standard configuration does NOT support.) | Yes( standard configuration does NOT support.) | GDI fuel injector:(Only PowerJET GDI S4)

|

| Injector resistance testing function | Yes | Yes | Yes | |

| RPM adjustable range:100~9900rpm, | Yes | Yes | Yes | GM TBI injector:

|

| Pulse width adjustable : 0.1~25ms, | Yes | Yes | Yes |

Optional Spare Parts

You may choose the optional spare parts below which are NOT included in the standard configuration.

Product Features:

High efficiency

The special structure design makes the disassembly and assembly of the oil separator easier.

High security

The unique oil circuit depressurization technology can make the machine automatically depressurize in the case of sudden shutdown, avoiding equipment damage or personal injury.

Strong cleaning

The machine has a strong ultrasonic cleaning ability, which can remove carbon deposits and impurities on the fuel injection nozzle to the greatest extent.

Real time monitoring

Thanks to the adoption of microcomputer automatic control and digital display technologies, the cleaning and testing processes can be controlled automatically and the parameters of the main status can be monitored in real time

Easy to control

Automatic fuel drain during a certain test can be realized via a routine, owing to the adoption of automatic fuel drain control technology. Start or [Stop] fuel drainage via the [Drain] button on the control panel in running or stop state

Humanization design

Adopting humanization design can make the system pressure fast restored to the default values

Product Functions:

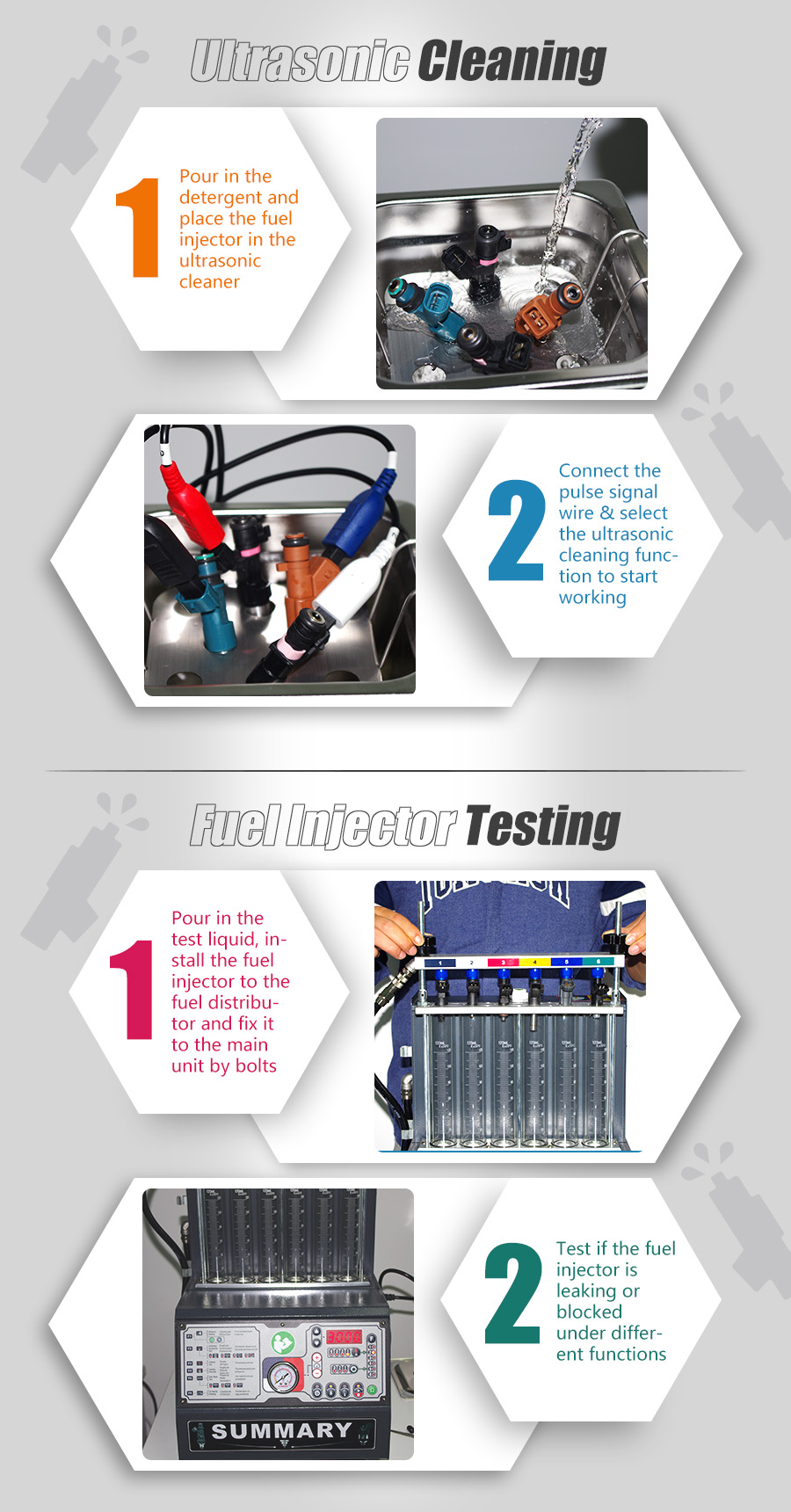

Ultrasonic cleaning

To clean injectors to remove the carbon deposition on them completely.

Uniformity test

To test the uniformity of injecting amount of each injector, and to monitor the spraying status of each injector with the help of backlight.

Leakage test

To test the sealing and dribbling conditions of injectors under system pressure.

On-Vehicle cleaning

Coming with a variety of disassembly-free cleaning connectors, the device can be used to perform on-vehicle cleaning and maintenance for various vehicle models.

Automatic test

Automatic fuel drain during a certain test can be realized via a routine, owing to the adoption of automatic fuel drain control technology.

Multi items setting

Set different parameters of the device, including the buzzer sound level, display brightness, and backlight brightness.

Why do we have to clean injectors?

When we turned off the engine suddenly, the gasoline which have been spray out can not be recycled. It would attached on the injector and combustion chamber walls. Gasoline is easy to volatile, but wax and varnish stayed. Heat these wax and varnish day after day,they will change into hard coke. The hard coke will be produced more quickly and more thickly when engine work with poor quality fuel.

Tips: Do not get any cleaning solvent on the outside of the vehicle, as this will damage the paint. A heavily clogged fuel injector may not allow enough cleaner to pass through during a routine cleaning, so it will not be adequately cleaned. Additional cleaning may be needed to clear heavy deposits.

Wide Vehicle Coverage:

SUMMARY POWERJET PRO 260 supports for 99% of vehicle models, and it fits for most petrol cars and motorcycles injectors, but NOT for diesel injectors.

Support for Audi,for Australia Ford,for Benz,for BMW,for Brilliance,for Chevrolet,for Chevy,for Chrysler,for Citroen,for Dacia,for Dadi,for Daewo,for Daihatsu,for Demo,for Fiat,for Ford,for GM,for Holden,for Honda,for Hyundai,for Isuzu,for Jaguar,for Kia,for Lancia,for Land Rover,for Mahindra,for Maruti,for Mazda,for Mitsubish,for Nissan,for Opel,for Peugeot,for Porsche,for Renault,for Romeo,for Rover,for Saab,for Seat,for Skoda,for Smart,for Subaru,for Suzuki,for Tata,for Toyota,for Volvo,for VW,for Yamaha,etc.

Easy Operation:

1. Clean injector's outside with gasoline or cleaning liquid before turning on the machine

2. Putting injectors in ultrasonic bathtub after the outside of injector is free of dirt.

3. Turn on ultrasonic system, allowing the ultrasonic energy to dislodge any particles even build-up inside the injectors.

4. Fix injectors on the machine

5. Test injectors for resistance, shorts, and current draw

6. Perform leak test, spray pattern, and flow rate testing on flow bench.

7. The injectors are now returned to the flow bench for retesting of all functions.

Product Specifications:

| Main unit power supply | AC110V±10% 60Hz |

| Input power | 230W |

| Ultrasonic cleaner power | 100W |

| Simulated RPM range | 100~9900rpm, step:10rpm |

| Time range | 5~300s, step:5s |

| Pulse width | 0.1~25ms,step: 0.1ms |

| Fuel tank capacity | 3.3ml |

| Work pressure | 0-7bar |

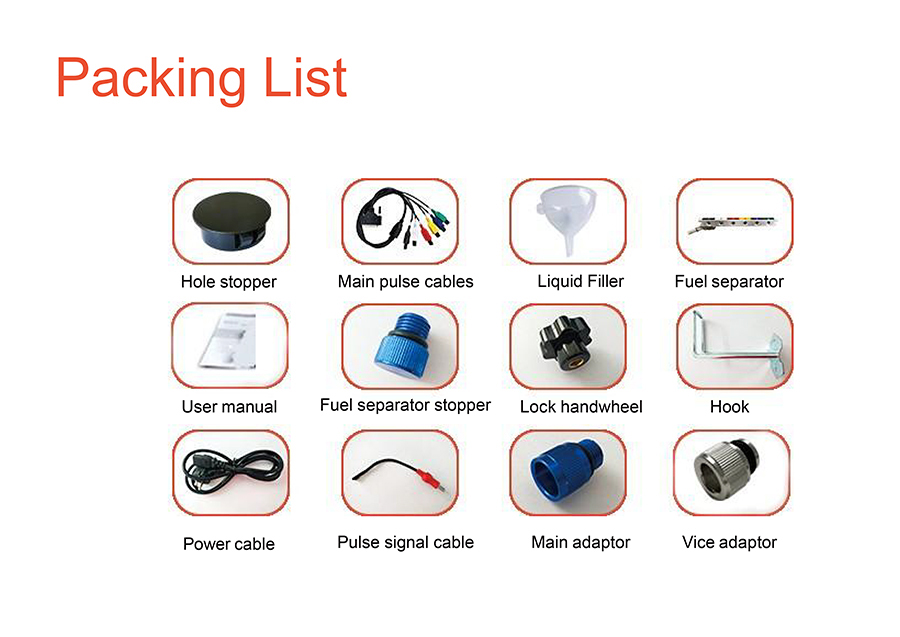

Package Includes:

1pc x Hole stopper

1pc x Main pulse cables

1pc x Liquid filler

1pc x Fuel separator

1pc x User manual

1pc x Fuel separator stopper

1pc x Lock handwheel

1pc x Hook

1pc x Power cable

1pc x Pulse signal cable

1pc x Main adaptor

1pc x Vice adaptor

Contact Information

Whatsapp: +86 1361282 7578

Email: info@getobdtool.com

Skype: getobdtool.com